T2Laser

What is T2Laser?

-- A replacement software controller for Benbox style laser engraving systems and other laser or CNC systems using Grbl firmware or requiring G-Code

Key Features

-- Image to G-Code Conversion

- Supports JPEG, BMP, PNG and GIF import

- Greyscale (S-value) and 1-Bit (dithered or threshold) conversion

- Velocity mode uses variable feed rates to produce greyscale

- CNC mode for 3D milling (Z-axis) or Laser Z-axis focusing

- Advanced raster-to-vector conversion with optional automatic hatch fill

- Resolution is user configurable

- Horizontal or diagonal engraving (45 degree engraving makes lines less visible)

- Skip "blank" lines (improves engraving speed by eliminating unnecessary moves)

- Image resize (uses an optimized algorithm to improve quality)

- Provides image adjustments (brightness, contrast, flip and rotation)

- G-Code can be saved (registered users only)

- Profiles are available to store and recall common settings

-- DXF and PLT Import

- Supports DXF/PLT import with colors translated to laser power or feed rates

- Multi-pass cutting for thicker materials (with optional cool down between repeats)

- Path optimization to reduce time and improve efficiency

- Adjust power or feed rate in each axis independently

- Vector resize, rotate and flip

- Use DXF colors to determine cutting sequence

- Output each color individually or sequentially with tool changes as needed (swap CNC bit or pen)

- Optional PDF conversion using an open source 3rd party utility

-- Gerber Import

- Load Standard (RS-274-D) and Extended (RS-274-X) Gerber files

- Aperture, Region and Drill Files are supported

-- Sketch and Trace (Raster to Vector)

- Create quick sketches using basic tools and text (includes arc text)

- Output as vector, hatch or raster (filled)

- Combine Sketch with image (add raster text or a vector path)

- Combine Trace vector (contour cut) with image

-- Laser Control

- Supports Grbl or Benbox firmware (S, L or P values can be used for laser power)

- PWM available with Grbl 0.9 or higher firmware and compatible hardware

- Upload firmware and default settings (no additional files or programs required)

- Load and edit G-Code files - supports raster and vector formats (registered users only)

- User interface for jogging (8-way) with step distance and set / return home

- Homing is supported with appropriate hardware

- Machine and workpiece position readouts, position presets for loading or jig positions

- Estimated time is displayed and progress bar / buffer state is shown when sending

- Laser on, off and pulse (using user configured power and time)

- Real-time laser and feed rate overrides available in Grbl 1.1 and higher

- Supports Dynamic Laser Power to prevent over burning due to acceleration

- Debug and Check modes are supported to verify G-Code before sending

- Emergency stop and fail safe error handling

- G-Code sender is optimized for small segments and constant power / feed adjustment

- Tested with files containing -7,000,000 lines of G-Code (trial is limited to 10,000 lines)

-- G-Code Viewer

- Supports laser power and variable feed rates for true representation of result

- Identify problems before sending to the laser

- Shows home and frame positions

- Run the G-code in the simulation to check cutting sequence

Installation

-- Download the latest T2Laser_Installer zip file

- If you are upgrading a version pre-1.4d, first uninstall using control panel (if registered, this will not affect your license key)

- Version 1.4d and later use web deployment and you will be notified of upgrades automatically (if connected to the internet)

-- Open the zip and review the end user license agreement (EULA)

- After acceptance of the license agreement, run setup.exe

- If needed, T2Laser can be uninstalled using the control panel

Laser Safety

- Always wear protective eyeglasses that are rated for the correct wavelength when the machine is powered on (the laser may energize unexpectedly)

- Do not leave the machine unattended while operating, if communications are interrupted the machine could stop with the laser on causing damage or fire

- Disable power saving modes (BIOS and/or OS), anti-virus and backup software that could affect normal operation

- Verify that materials being engraved or cut are "laser safe" and do not produce harmful vapors and also maintain adequate ventilation

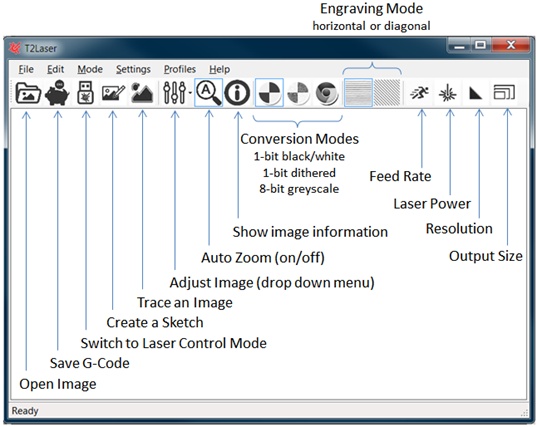

Main Window

(Design Screen)

-- Open Image

- Load a raster image (JPG, BMP, PNG or GIF)

- Right click to import a vector in AutoCAD DXF or HPGL PLT format (see Vector Import section)

-- Save G-Code

- Processes the image and saves the G-Code file

-- Control Laser

- Switches to the laser control screen

-- Sketch

- Create a raster or vector drawing (see Sketch section)

- Right click to load a Sketch or Sketch Template file

-- Trace Image

- Raster-to-Vector conversion of the loaded image (see Trace section)

- Auto Trace can be used to convert the entire image

-- Edit Image

- Brightness, contrast and gamma adjustment

- Rotate image clockwise or counter-clockwise

- Flip the image (useful for back engraving mirrors)

- Invert the image (produce a negative image)

-- Auto Zoom

- z key toggles on/off

- 100% (actual view)

- Zoom to fit window

-- Show Image Information

- i key toggles on/off

- Displays the image size in pixels and millimeters

- Shows DXF extents, count of line segments and shapes

-- Image to G-Code Conversion Mode

- 1-bit black and white (best for text or drawings)

- Dithered (Floyd Steinberg diffusion method), pixels are black or white (min or max power)

- Greyscale (Laser power changes based on pixel value, black represents maximum power)

- Click on image to show original (color if applicable)

-- Engraving Mode

- Horizontal (lines are scanned along the X-axis)

- Diagonal (scans using X and Y simultaneously, eliminates "screen door effect")

-- Feed Rate

- Sets the default engraving speed

- Right click to set the rapid feed rate (speed when laser is off)

-- Laser Power

- Sets the minimum and maximum laser power values

- Default 0-255 but can be changed for different configurations

-- Resolution

- Sets the output line resolution for image conversion

- 0.1 mm line resolution = 10 lines per mm or 254 DPI

- Lower values will have a higher resolution but take longer to process

- Determines the auto-join gap for DXF segments

-- Output Size

- Sets the output dimensions for raster images

- Can also be used to re-scale vector data (it is recommended to set the correct size in your CAD program before exporting)

- Image is resized (uses an optimized algorithm to improve quality)

- It is recommended to set resolution before output size

-- Additional Menu Items (not available on the toolbar)

- File

- Import GBR

o Loads Standard (RS-274-D) or Extended (RS-274-X) Gerber files

o Set the resolution before importing

o The drawing is loaded as an image and can be processed using the edit image tools

o Standard format requires an aperture file (.APT) in the same directory with either the same name or prefix as the Gerber file

o Drill files (.DRL) with either the same name or prefix as the Gerber file in the same directory can be overlayed (negative)

- Convert PDF

o Converts Adobe PDF files to AutoCAD DXF format and loads the vector data in T2Laser

o Requires installation of the optional Convert2DxfCmd application developed by Agastar on the benboxlaser.us forum

- Sketch Template

o Loads a T2Laser Sketch Template

- Clear

o Image, Sketch and/or Vector data is deleted

- Edit

- Auto Trace...

o Converts the entire image from Raster-to-Vector

- Crop Image

o Select a portion of the loaded image

- Mode

- Photo Mode

o Uses a pixel shifting algorithm (similar to anti-aliasing) to blend the grey levels for a more natural look.

o Produces a "softer" image (not recommended for clip art)

o This algorithm will be used if a suitable image is detected and does not normally need to be manually selected

- Velocity Mode

o Uses variable feed rate to produce a greyscale result

o Rapid and standard feed rates must be set correctly

- Sketch (Filled)

o Sketch is created as a raster image (text or shapes will be filled)

o See the Sketch section for examples and additional details of use

- Sketch (Hatch)

o Sketch is created as a vector with pseudo fill using lines

o See the Sketch Hatch section for examples and additional details of use

- Sketch Plus (Overlay)

o Combines raster or vector Sketch with the loaded raster image

o Allows contour cutting or adding text to an image

o See the Sketch section for examples and additional details of use

- Settings

- Multi-Pass (Vector)

o Repeats the vector path multiple times to enable cutting of thicker materials

o Pre-defined or custom repeats (unlimited)

- Cool Down Delay

o Used with above option to dwell after each pass for laser to cool down

- Matrix Copy (Sketch)

o Generates Step and Repeats for Sketch drawings

o Set parameters for columns (X), rows (Y) and gap (spacing in mm)

o Note: You must disable multi-pass and select lower left start position

- Center (Start Point)

o Position the laser (and set home) in the center of the job (between extents) before starting

o Absolute option uses the entire drawing from 0,0 to maximum extents for center position

- Corner (Start Point)

o Lower left start is the default location, lower right, upper left and upper right are options

o Position the laser (and set home) at the corner of the job before starting

o This option can be used with Gerber files to enable back side alignment

- Use Extents for Frame

o Force the frame to use drawing extents (instead of including 0,0)

- Skip Blank Lines (default)

o Speeds up engraving by skipping blank areas within the job

- Laser (Z-Axis Focus)

o Use S values for laser power but enables manual Z-jog controls

- CNC Mode (Z-Axis)

o Use Z-Axis values

o Enter the maximum Z-depth

o Top of material is defined as Z0 (typically with positive values down)

o Optionally enable depth per passes (Z-depth will be divided equally between each multi-pass)

o Optionally set a Z-safe height (typically a negative value)

o Set a spindle speed (max is usually 255 or 1000 depending on firmware)

o Optionally set a spindle delay in seconds (allows the spindle to get up to speed)

- Threshold (B/W)

o Sets the pixel threshold for 1-bit black and white conversion

o Transparency is converted to white (laser off)

- Image Options

- Bi-Directional Scanning (default)

o Horizontal scan mode follows a serpentine pattern

o Disabling will scan left to right only

- Rapid Skip Blank

o Use the rapid feed rate in blank areas (faster)

- Skip Solid Lines

o Used only for CNC systems or special purposes

- Over-Scan

o Forces laser to remain on during horizontal line transition

o Likely to produce a darker edge to the image

- Transparency to White

o Used with PNG files. Any transparent region is converted to white (or black if unchecked)

- Trace Resize (Single Mode)

o When enabled (default) the Trace resolution is maintained when scaling for improved detail

o Disable to reduce the path which will lose some detail but may improve engraving speed

- Eliminate (Trace) Noise

o Removes objects smaller than 5mm² (clean up result but may lose some fine detail)

- DXF Options (note: options marked with * only have an effect at load)

- Relocate Origin (works with vector files and Trace feature)

o The origin (0,0) is set at the minimum drawing extents

- DXF Optimizer (also works with PLT files)

o Changes the sequence of vector segments and paths to reduce run-time

o Options to override start point and/or allow segment reversal

o Can also force auto-joining of open shapes (this may distort the file, check the view before using)

o Use DXF colors to determine cutting sequence (Yellow, Green, Blue, Orange, Red and Black)

- Override DXF Units*

o If checked, values are used as metric and header is ignored (no conversion)

o Option to force conversion (header is ignored, values are treated as inch units)

- Select Output Color

o All (default) sends all colors with their corresponding power values in the order generated

o Sequential sends each color in series using reverse order (5=Yellow, 4=Green, 3=Blue, 2=Orange, 1=Red and 0=Black)

o Select an individual color to send only that color

o Sequential and Individual colors default to max laser power unless Use Power Value is selected

- DXF Color to Feed Rate

o Adjusts the feed rate (instead of laser power) based on DXF color, works with non-PWM laser modules

o Black (Feed Rate), Red, Orange, Blue, Green and Yellow (Rapid Feed Rate)

- Absolute DXF Colors

o Uses an absolute percentage of the power or feed rate based on color (method used in earlier version)

o Black 100%, Red 80%, Orange 60%, Blue 40%, Green 20% and Yellow 0% (increment percentage can be changed)

- Vector Adjustment

o Linearly increases power or feed rate based on the vector (angle) of motion

o Swap XY changes the vector (default is lower power or higher feed rate in X-axis)

o Set percentage value to adjust (e.g. add 20% to the feed rate or power when perpendicular to the axis)

- Ignore Bulges*

o When enabled the bulge parameter is ignored (converted to straight lines)

- Reverse DXF Paths*

o Set before import to reverse the path direction

o Typical paths are engraved counter clockwise with this option disabled

- Reverse DXF Segments (default)*

o Each segment within the DXF path is reversed (necessary for some software)

- Skip Minimum Power

o When selected any minimum power (yellow) segments will be skipped (default)

- Advanced Settings

- Silent Mode

o Does not ask to generate or save G-code (defaults to Yes and No respectively)

- Auto-Crop Sketch

o When selected the Sketch will automatically be cropped to extents when generating the G-code

o Use the manual crop (Resize Canvas) option in Sketch if you want to adjust or add a border

- Skip Sketch Template

o When selected a Sketch Template will only output the user editable objects

- End Program (M30)

o Issues a G-Code end program command after the job completes

o This is necessary on some systems to completely disable the laser

o Workpiece home position will be lost (recommend setting machine home)

- Gerber Options

o Set the units and accuracy for Gerber files (only required if header information is unavailable)

o Additional settings to ignore aperture data or use drill files

- Hatch Options

o Use Vertical, Diagonal lines (right click to change from / to \) or Cross Hatch (right click to change from x to +)

o Change the spacing between lines; narrow, default, wide or custom

o Exclude the outline so only the fill is engraved

- Anti-Alias Display

o Helps reduce moiré patterns on computer screen only, does not affect output

- Keep Display On

o Forces your display to remain on while T2Laser is running

- Insomnia Mode

o Prevents your computer from sleeping (can be temporarily disabled but will reset to on at startup)

- Disable Image Adjustment

o When selected Image Adjustments will be disabled (e.g. brightness, contrast, flip and rotation)

o Enable when using very large images to reduce memory and resource usage

- Splash Screen

o When enabled a T2Laser or corporate partner logo will be displayed at start-up

o Option 0 will load a random background, other values load the specified image

- Profiles

- Click to load a preset profile

o Includes feed rate, min/max laser power, resolution, passes and cool down

- Set parameters and then right click on the profile to edit the name and save settings

o Previous settings will be overwritten

- Profile Management

o Backup or restore profiles (save to a text file)

- Help

- About

o Shows version number

o Register the trial version (see the Register section for more details)

- Manual

o This document

- YouTube Channel

o Videos explaining the basic operation of T2Laser

- Samples

o Built-in files which can be used to test your machine

- Change Language

o Used to override the automatic language selection (temporarily)

o Deselect the "Automatic" selection to permanently use the manual selection

- Restore Defaults

o Resets the user settings to their default values

- Security Dongle

o Use a hardware security device for license verification

- Install CH340 Driver

o This installs the USB-to-Serial COM driver for the CH340 chipset

- Check for Updates

o This is for beta testers only (pre-release versions) and requires a password to install

o You will be notified automatically when a new release is available (must be connected to the internet)

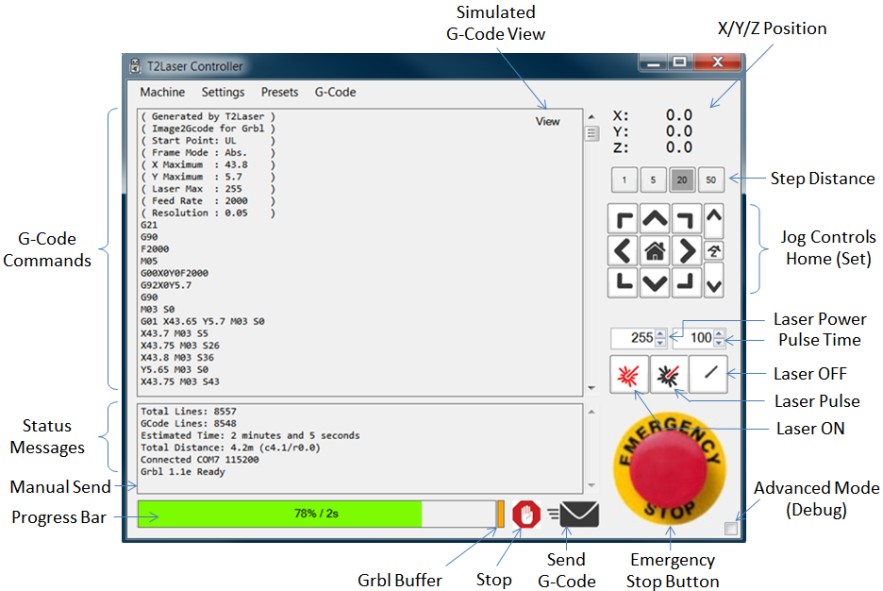

Laser Control

Window (shown connected)

-- Connect Settings

- Select Port and Baud Rate

- Click the lightning bolt or select Connect in the Machine menu to connect

- If no ports are shown check connection and click lightning bolt to re-scan

- USB driver for your device must be installed

- Once the COM port is open the status message "Connected" will be displayed

- If the Grbl firmware begins communication the message "Grbl Ready" will be displayed (the version may also be displayed)

- If Benbox firmware is detected the message "Benbox Ready" will be displayed

-- Firmware Upload

- Select COM port and click Upload Firmware (x.x) from the Machine menu

- 1.1e (default) includes support for homing on D9 and dynamic laser power [enable in the Settings / Advanced menu]

- 0.9g J-Tech. Supports most systems, uses 7.8KHz PWM [once installed use 'Send Default Parameters' to load T2Laser default values]

- 0.9i EleksMana. Use for EleksDraw or EleksEgg systems that require either Servo or CoreXY control (see sub menu for configuration)

- 0.9j Woodpecker. For use with their CNC controller boards

- 1.1e Non-PWM. Uses D12 for the laser, not officially supported [automatically enabled in the Settings / Advanced menu]

- 1.1e Axis Swap. Same as default except X and Y axis are swapped

- 1.1f LaserAxe. Uses custom pin outs for some of their machines (others can use the default firmware)

- 1.1f High Frequency PWM. Uses 7.8kHz instead of the standard 1kHz PWM

- Alternative method; Disconnect your machine (right click the stop button) or select Disconnect from the Machine menu, then select COM port and Ctrl-Click the lightning bolt to upload Grbl 0.9 laser firmware. There should not be any G-Code loaded in the command window

-- Grbl Parameter Upload

- Ctrl-Click the Send G-Code (envelope) or select Send Default Parameters from the Machine menu to upload the default parameters

- Check the status messages to confirm parameters were uploaded correctly, repeat as needed

-- G-Code Commands

- This window displays the current program

- Double click the window or click Load G-Code from the Machine menu to load a G-Code (.nc) program file

- When disconnected from the laser, G-Code can be edited

-- Status Messages

- Important system messages and responses from Grbl are shown here

- Double click to clear the status messages

-- X/Y Positions

- After connecting the current X/Y (Z) positions are displayed

- Double click to switch between machine and workpiece positions or select Machine Coordinates from the Settings menu

- Machine positions are shown as *X and *Y (*Z)

- If machine is moving the positions are displayed in red

-- Step Distance

- Select the distance to be moved during a manual jog (mm)

-- Home (Origin)

- Click to return to the workpiece home position (not the machine origin)

- Right click the home icon or select Set Origin (Workpiece) from the Machine menu to set workpiece home position (a soft reset clears the workpiece home position)

- If Machine Coordinates are displayed, right clicking will request to run the Home (Machine) procedure, if you select no the Set Origin (Workpiece) command will run

-- Home (Machine)

- Typically used with home/limit switches (Grbl must be manually configured for your setup)

- If home switches are not enabled this sets the persistent machine offset

- Enable homing with the Home Switches option in the Settings menu

- Select Home (Machine) from the Machine menu to start the homing procedure or set the machine offset

- If Reset Workpiece Origin is selected in the Settings menu the machine offset will be set once homing is complete

-- Jog Buttons

- Move (step distance) in the direction selected

- If Z-Axis Focus or CNC Mode are selected the Z jog keys will be available

- Cursor keys (arrows) work when step is set at 20 or less, home key goes to workpiece origin

-- Laser Power

- Select the laser power from 0-255 used for manual laser operation

-- Pulse Time

- Select the manual laser pulse time in milliseconds

-- Manual Laser Controls

- Switch the laser on using the power setting specified above

- Pulse the laser using the power and pulse time specified above

- Switch the laser off

-- Send G-Code (start the program)

- Click the envelope or select Send G-Code from the Machine menu to begin sending the loaded G-Code to the machine

- While running, click to pause and again to resume or restart the G-Code program

- Commands already in the Grbl buffer will be processed before the machine halts

- If a tool change is required, sending will pause until you confirm the change was completed (do not click OK until clear of the machine)

-- Stop Button

- G-Code sending is halted, after a few seconds the machine will stop

- The laser will be turned off

- The machine will return to workpiece home

-- Emergency Stop (left click)

- Soft reset, the machine will come to a controlled stop

- The laser will be turned off

- Workpiece home will be cleared

- Current XY position will be maintained

- ESC key performs the same function

-- Emergency Stop (right click)

- Right click the stop button to perform an immediate (emergency) stop

- The laser will be turned off and the connection terminated

- XY positions may be inaccurate (if the machine is moving some steps can be lost)

-- Progress Bar

- Shows the transfer progress as the G-Code file is processed

- The far right block shows the Grbl buffer status

- During transfer it should flash red (full) to orange (almost full)

-- Debug Mode

- Click to enable or select Advanced Mode from the Settings menu

- The manual G-Code command box is displayed

o Enter commands and click enter to send (used to change Grbl parameters)

- Additional messages are displayed in the status window during communication

- This should be disabled when not required to maximize performance

-- Rotary Axis

- Click to enable (opens the setup page) or disable

- Right click to change the settings without disabling

- First time setup (settings are stored)

- Select the axis you are replacing

- If the rotary axis is opposite to your standard axis, select the reverse check box

- Enter the steps per rotation using the formula shown (motor steps per rev * micro-stepping * drive ratio)

- Your original values are automatically stored and should not need to be changed (these are used when rotary axis is disabled)

- Enter the item diameter or circumference

- The calculated steps per mm will be displayed in the pending changes section, click OK to send these changes to your Nano

-- Presets

- These user presets store the machine and workpiece coordinates

- Click to recall the preset and move to the location specified

- Right click to save the current positions (optionally enter a name)

- If Use Machine Positions is selected (default) the stored machine coordinates are used

-- Advanced Features

- Disconnect machine

- Right click the Stop button to disconnect.

- Sleep Mode

- If using Grbl 1.x or later and motor are always energized you can use place the machine in a sleep mode, clicking again wakes the machine

- Display Grbl Parameters

- Ctrl-Click the Home button or select Display Grbl Parameters from the Machine menu to download/view Grbl parameters

- Reset Grbl Parameters

- Restores all $ values to the original firmware settings (these are the T2Laser defaults if using v1.x firmware)

- Clear Grbl Positions

- Clears all stored positions (if your coordinate display is not showing 0,0 after connecting this will clear the offset)

- Reverse Axis Directions

- Use the Reverse X/Y/Z-Axis Direction options in the Settings menu

- Z Axis Jog Control

- Enabled the Z axis jog buttons (option to reverse the jog key directions)

- Laser Power Override

- Right click the laser power value or select Override Laser Power from the Machine menu to override laser power in loaded G-Code file

- The values will be rescaled using the selected value as maximum (based on 255 as maximum or 100%)

- Right click power value and select no to cancel override and return to original values

- Feed Rate Override

- Right click pulse time value or select Override Feed Rate from the Machine menu to override the feed rate in the loaded G-Code file

- Enter a new value and click OK, or select cancel to cancel the override

- Real-Time Feed Rate and Laser Power Override (only available with Grbl 1.x or above)

- When running the override options will be displayed

- Click + or - to change the override percentage or click 100% to return to G-code values

- Feed rate can be set between 10% and 200%, Power between 50% and 200%

- Draw the frame / border (for alignment)

- Right click the laser on button or select Engrave Frame from the Machine menu to laser the frame at the specified power level

- Right click the laser off button or select Trace Frame from the Machine menu to trace the frame with the laser off

- Check Mode

- When enabled G-Code is parsed by Grbl but not sent to the laser, this is used to check the code for any errors before starting the job

- Post Processors

- Grbl (default), uses S values for laser power control

- Benbox compatible G-code

- LaserBot mode uses P values for laser power (this is experimental and still in development)

- Laser D12 (used with the non-PWM firmware on older hardware that does not support D11 laser signals)

- Configure EleksMana (only for use with the EleksMana firmware)

- Click to select your machine; Laser, Draw, Egg or Mill

- Click to change modes; Laser, Servo, Cartesian or CoreXY

- Advanced

- Dynamic Laser Power, adjusts laser output based on feed rate to prevent over-burning at the start and end of lines or dots at corners

- Estimated Time Remaining, displays the ETR in the progress bar during send (this is approximate)

- Alternate Jog Increments, use reduced (1/10th) values for jog distances (right click on jog buttons to switch mode)

- Display Custom Buttons to run user editable G-code. Right click to enter the name and commands (use | to indicate line breaks)

- When Jog Rapid Feed is enabled, jogging will use the rapid feed rate instead of machine maximum speed as determined by Grbl parameters

- When Frame Rapid Feed is checked rapid feed rate will be used instead of vector feed rate for Engrave and Trace Frame

- Hold Position keeps the motors energized to prevent accidental movement but may cause overheating and failure of the motor or driver

- Fast Status increases the coordinate refresh rate (X5) but can overload the microprocessor

- Reduced Acceleration, use slower ramp rates to minimize backlash and/or lost steps on systems which are not mechanically optimized

- Machine Size uploads the default machine size set in Sketch to the Grbl parameters. This is only required if you have home or limit switches

- If selected DTR sets the Data Terminal Ready pin (default)

- Fail-Safe Mode (attempts to disable the laser if any errors are detected)

- Low Buffer Mode, reduces the Grbl buffer (for diagnostic purposes only)

- Laser Mode, should be enabled for lasers (even if they have a Z-axis) and disabled for CNC machines using a spindle

- Clean G-Code (Aggressive), this may fix imported G-code errors (Note: Use caution as G-code may be corrupted)

-- View

- Display a simulation of the G-Code

- Laser power is shown from yellow to blue (max power)

- Press ‘o’ to show laser off as yellow

- Press ‘b’ to show laser min as red and laser off as black

- Press ‘r’ to show laser power using DXF colors (see below)

- Press ‘s’ to run the g-code

- ‘q’ changes speed (4 levels)

- Press ‘s’ again to stop the simulation

- Use the 0, 1 and 2 keys to change the laser width (default is 0)

- Press 'g' to show/hide the origin (start) point

- Press 'f' to show/hide the frame

- Press 'd' to show/hide the dimensions (lower left and upper right positions)

Vector Import

-- AutoCAD .DXF files in 7-bit text format

- Supports the following objects; Line, Polyline, Circle, Arc, Ellipse, E-Arc and Spline

- Explode blocks and text before exporting

- Colors are mapped to power or feed rate (a custom palette for Inkscape is available)

- Default uses the range from max to min laser power or feed rate to rapid feed rate

- Using the Absolute DXF Colors option: Black 100%, Red 80%, Orange/Purple 60%, Blue 40%, Green 20%, Yellow 0%

- Refer to T2Laser_DXF-Conversion for additional information

-- Corel HPGL PLT files

- Refer to T2Laser_PLT-Conversion for additional information

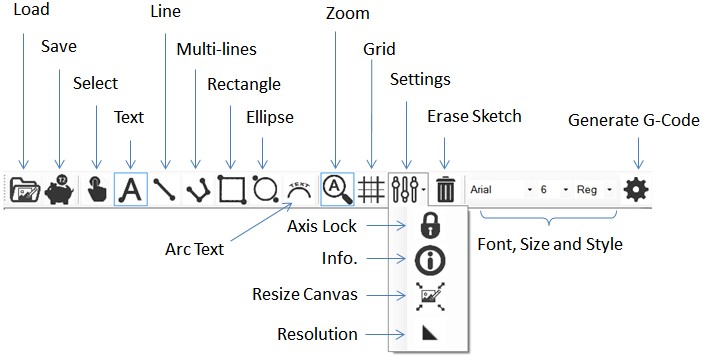

Sketch

-- Use the page size required for your Sketch

- Select your machine or custom to enter the required sizes

-- Load

- Opens a T2Laser Sketch (.t2s format)

-- Save

- Save the current drawing as a T2Laser Sketch file

-- Select

- Click outline or hold shift key to select inside object

- Click and drag to move or use right mouse button to resize

-- Text

- Click on page at insertion point and type text

- Use pipe | symbol to add a new line between text (or enter text in parameter screen)

- Use select tool to highlight text to change font, size or style

- With text selected

- Press C key to change alignment (left, center and right)

- Press F key to mirror text (flip across vertical axis)

-- Line

- Click start and end points

-- Multi-Line (Polyline)

- Click to add points

- Right click to close the shape

-- Rectangle (or Square)

- Click to start and end rectangle (corners)

-- Ellipse (or Circle)

- Click to start and end ellipse

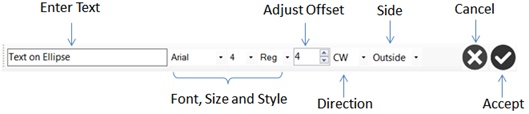

-- Arc Text

- Select an ellipse or circle first and then click the Arc Text icon

- This is a temporary object and can be deleted later

- It can also be used multiple times to add text to the top and bottom as needed

- Enter text and adjust settings (a preview is displayed)

- The parent ellipse rotation will affect the result

- CCW text will appear correct on the bottom or upside down if moved to the top

- Click accept to generate the arc text or cancel to abort (arc text is not generated)

-- Zoom

- Toggle Auto-Zoom (scale to fit)

- Right click to change zoom (1X, 2X and 5X)

-- Grid

- Enable or disable the grid

- Right click to swap between 10 mm and 5 mm spacing

-- Axis Lock

- Lock to X/Y axis or aspect ratio 1:1 for circles and squares

-- Info

- Show or hide the overlay

- Displays document size, magnification, grid size and count of shapes and segments

-- Resize Canvas

- Enlarge or reduce the the Sketch drawing size

- Click the center icon to automatically select the drawing extents

-- Resize (Rescale) Sketch

- Sketch is rescaled to the new size (fonts and arc text may need to be manually edited after rescaling)

-- Resolution

- Resolution used for node/point spacing in ellipses and text

-- Combine Paths

- Automatically joins overlapping paths (use with script style fonts)

-- Erase

- Clears the entire Sketch

-- Font Settings

- Select the Font, Font Size and Font Style

- If text is selected you can scroll through the list to see the result

-- Generate G-Code

- Finish the Sketch and generate the G-Code

- Save the Sketch before exiting (if needed)

- You can return to the Sketch later and save or edit it as required

-- Additional Keys

- Press Delete to erase selected object

- Press L and R to rotate object

- Press F to flip the object (Y-axis)

- Press P to open the parameter entry screen (move or change object)

- Press Ctrl to toggle axis lock

Sketch Plus

-- Modes

- Sketch

- No options selected

- Output as an outline – vector

- Sketch Filled

- Sketch Filled selected

- Output is solid – raster

- Sketch Hatch

- Sketch Filled with a selectable Hatch Pattern (pseudo fill)

- Sketch Plus

- Sketch Plus is selected

- Sketch outline is added to the loaded image – raster + vector

- Sketch Filled Plus

- Sketch Filled and Sketch Plus are selected

- Solid Sketch output is added to the loaded image – raster

- Sketch outline is added to the solid Sketch – raster + vector (no image loaded)

- Trace

- No options selected

- Trace outline is output – vector

- Trace Hatch

- Sketch Hatch is enabled

- Trace is output as a vector with hatch pattern

- Trace Contour

- Sketch Plus selected

- Trace vector is added to the image raster – raster + vector

- Sketch Filled + Sketch Plus

- Text is added in Sketch and combined with image as final raster output

- Sketch Filled + Sketch Plus (no image)

- The text outline is added to filled text (result in a darker crisp edge to the text)

- Trace Contour (using Sketch Plus)

- Vector is shown in red and added to the raster image (used for cutting out the image)

Engraving Modes

- The default mode will auto-detect and use photo mode as needed to improve the results

- Manually selecting photo mode is not recommended especially for clip art / logo engraving

- Unidirectional is significantly slower but allows the laser to cool between lines and reduces "zig-zag" errors on systems with excessive backlash

- Use diagonal mode to improve results with wood grain

- All modes include over-scan on the trailing side to reduce dark edges caused by deceleration

Trace (Raster-to-Vector Conversion)

-- Open Image

- Clipart style high contrast images work the best

- Adjust image and select settings prior to conversion

- Select Trace Image from the tool bar or edit menu

- Click the outline(s) to trace and right click to see just the result

- Turn off trace when complete to generate the G-Code

- G-Code will automatically be generated when clicking Save or Control Laser

- Resize Trace (use the output size button)

- Does not work if hatching is applied, resize the image before tracing if hatch is required

- Do not increase the trace size, instead resize the image and re-trace for improved quality

- Trace Resize (Single Mode) should be enabled for highest detail but can be disabled (see Image Options)

Change Log

-- v1.4j adds crop image feature, auto-crop sketch to extents (sketch + settings), Aussie z-jog, resize "trace" with enhanced detail, beta tester option for updates

--

v1.4k adds Russian and Korean languages, Sketch matrix copy (step and repeat),

file name on G-code header, custom G-code buttons, "splash" screens

added option for CNC Z-Safe height

and depth per pass, aggressive G-code cleaner (automatically correct imported

code), password for beta updates

--

v1.4m tool (pen) change to support EleksDraw or CNC, use spindle speed and

safe Z height for raster CNC mode, fixed "view" for CNC with negative values

Keyboard Shortcuts

-- Design Screen

- Open Image, Ctrl-O

- Import DXF, Ctrl-I

- Import PLT, Ctrl-P

- Save G-Code, Ctrl-S

- New Sketch, Ctrl-N

- Laser Control, Ctrl-L

- About, F1

- Manual, Shift-F1

- Information Overlay, I

- Zoom (Auto), Z

-- Sketch

- Rotate, L and R

- Text Alignment, C

- Flip, F

- Parameter (Edit Mode), P

- Lock Axis, Ctrl

- Information Overlay, I

- Zoom (Auto), Z

-- Laser Controller

- Emergency Stop, ESC

- Jog (Move Axis), Cursor Keys

- Home (Goto), Home Key

-- G-Code Viewer (Simulation)

- Show Origin, G

- Show Frame, F

- Show Dimensions, D

- Start / Stop Simulation, S

- Change Speed, Q

- Show Laser (Off), O

- Show Laser Disabled, B

- Use DXF Power Colors, R

- Laser Width, 0, 1 and 2

Mouse Quick-Clicks

-- Design Screen

- Open Vector, Right click Open Image icon

- Load Sketch, Right click Sketch icon

- Auto Trace, Right click Trace icon

- Show Original Image, Click the Image

- Rapid Feed Rate, Right click the Feed Rate icon

- Relocate Origin, Right click the Relocate Origin menu item for one-time fix

- Optimize DXF, Right click the Optimize DXF menu item for one-time fix

- Save Profiles, Right click to Save Profile

-- Sketch

- Zoom Setting, Right click Zoom Icon

- Grid Size, Right click Grid icon

- Move Object, Click drag on selected object

- Size Object, Right click drag on selected object

-- Laser Controller

- Disconnect, Right click the Emergency Stop button

- Clear Status Messages, Double click the status message window

- Machine Position, Double click the display to switch between machine and workpiece coordinates

- Set Home (Origin), Right click the Home icon (when workpiece coordinates are displayed)

- Home Machine, Right click the Home icon (when machine coordinates are displayed)

- Pause G-code, Press the send envelope while running (press again to resume)

- Save Presets, Right click to save current position as a preset location

- Show Grbl Parameters, Hold the Ctrl-key and click the Home icon to display the Grbl parameters

- Trace Frame, Right click the laser off button

- Engrave Frame, Right click the laser on button

Troubleshooting & FAQ's

-- Why is the laser always on?

- This is likely because of a mismatch between the firmware version (Grbl) and the hardware setting

- Move the jumper under the Nano microprocessor board to the correct location or use the correct firmware

-- Images don't load at the size they were saved?

- The image size is based on the number of pixels and the resolution

- An image 1000 x 1000 px at 0.1 resolution would be 100 x 100 mm

-- How do I "outline" an image?

- An image is a raster format, to cut or engrave it's perimeter you need to convert it to vector by tracing it

- Use the Trace Image or Auto Trace feature in the Edit menu

-- Text isn't importing on vector (DXF) files?

- Text must be exploded or converted to a path before exporting from your CAD program

-- Why aren't my vector (DXF) files filled?

- Vector files are paths only, if you want to "fill" them you need to apply a hatch pattern in the CAD program and save it as a path

-- My sizes aren't coming out correctly?

- If the on-screen size is correct, this is usually because you don't have the correct Grbl parameters loaded

- Use the firmware provided with T2Laser that includes the defaults (currently 1.1e) or click "Send Default Parameters" from the Machine menu

-- How can I improve my grey-scale images?

- The best results require a TTL laser but many non-TTL lasers will provide satisfactory results using the PWM method

- If you are unable to get good results, you can use the "dithered" mode which produces excellent pseudo grey-scale

-- What "mode" should I use?

- For images select grey-scale or dithered, for clip art or logos use black and white mode

-- My laser says "connected" but it isn't working?

- "Connected" means you have opened the COM port, if you don't get a "Grbl Ready" or similar message your laser isn't responding

- Disconnect and verify you have the correct port selected, if so, try uploading the Grbl firmware

-- I don't have any COM ports?

- The COM port is actually a USB driver, check Device Manager for issues (red X) and load the correct driver for your machine

- Most of the Nano clones require the CH34X driver, genuine Arduino Nano's use the FTDI FT232 driver

-- How much does T2Laser cost and where do I get it?

-

T2Laser is trial software, you can download it from

www.t2laser.org and

should test it with your machine before purchasing

-

When you are ready to purchase, a non-transferable single PC license is $39.95

and should be purchased directly from the software

-- I need T2Laser on multiple PC's, do I have to purchase a license for each?

- Yes, we offer 2nd licenses at 20% discount or we have other licensing options available. Please contact us for details

-- How do I upgrade T2Laser?

- T2Laser includes free minor updates for the life of the license

- You will be notified when updates are available and installation is automatic

-- I replaced my computer and now my license key won't work?

- The license is tied to the computer, you will need to purchase a replacement license for the new computer (50% off)

-- I reformatted my computer or replaced the hard drive and now the key isn't recognized?

- If you had to reactivate Windows it is possible Microsoft issued your computer a new ID

- Type "HK" (upper case, without the quotes) in the key code box and provide those hardware values

- If they match your original computer we can generate a replacement key free of charge

Trial Limitations

-- The trial version is for evaluation purposes only, to verify your hardware and this software are compatible and that it meets your requirements

-- Limitations include but are not restricted to

- G-Code and Sketch save is disabled

- G-Code generation is limited to 10,000 lines for raster (1,000 lines for vector)

- Each session is limited to 15 minutes (the program will terminate without warning)

Purchase and Registration

-- All purchases are final and non-refundable, please evaluate it using the trial before purchase

-- The provided license (registration code) is for a single computer (review the EULA for details)

- If you plan to reformat the hard drive or re-load the operating system it is recommended to save the Hardware ID information and send to software@t2laser.org

- Registering unlocks all features, provides free updates and unlimited e-mail support

- To register on the computer you want to license click the PayPal "Buy Now" button

- If you want to register another computer or transfer your license, please e-mail your User ID to sales@t2laser.org

- After payment confirmation we will manually generate and e-mail the key code to register the software - this may take up to 48 hours (it is usually much less)

- Copy/paste the Key Code directly to the box on the registration window

-- Alternate licensing options are available at additional cost

- These include using a licensed Nano or a USB security "dongle" key, contact sales@t2laser.org for details